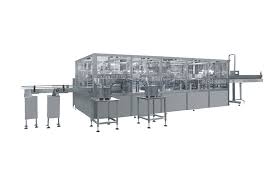

Bottle Filling Line (100ml To 500ml – LVP Line)

A Bottle Filling Line (100ml to 500ml – LVP Line) is an advanced automated system used for filling large-volume parenteral (LVP) solutions into bottles. It is widely utilized in pharmaceutical, biotech, and healthcare industries to ensure precise, sterile, and contamination-free liquid filling.

The process begins with bottle washing, where bottles are cleaned using purified water and compressed air to remove any impurities. They are then transferred to the sterilization tunnel, where they are dried and sterilized to maintain aseptic conditions.

Once sterilized, bottles move to the filling station, where liquid solutions are accurately dispensed using volumetric, peristaltic, or gravity-based filling technology. After filling, the bottles proceed to the capping and sealing section, where caps or rubber stoppers are securely placed and sealed.

Post-sealing, bottles undergo leak testing and inspection to detect defects or contamination. Advanced lines also feature labeling and packaging stations for final product preparation.

This automated system ensures high efficiency, precision, and compliance with Good Manufacturing Practices (GMP) and regulatory standards, making it essential for safe and sterile liquid production.